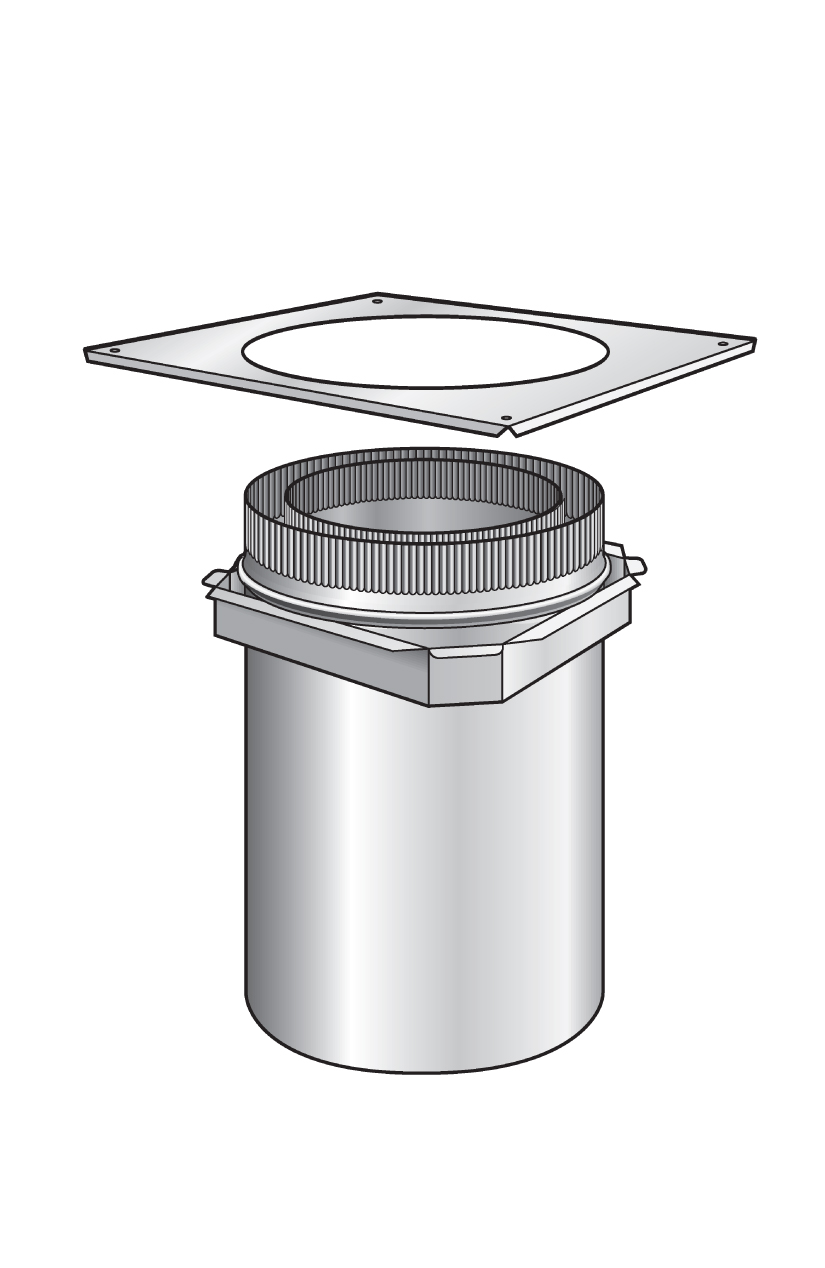

Floor Penetration Unit 150/200/250 Installation Instructions

../Installation Guides/Floor Penetration Unit 150/200/250 Installation Guide

THIS PRODUCT HAS BEEN MANUFACTURED IN ACCORDANCE WITH AS/NZS 2918:2001. TO ENSURE SAFETY THIS PRODUCT MUST BE INSTALLED AS OUTLINED IN THESE INSTRUCTIONS.

CLEARANCE OF HEATER AND FLUE PIPE FROM COMBUSTIBLE WALLS MUST BE IN ACCORDANCE WITH THE REQUIREMENTS OF AS/NZS2918:2001

For heaters not tested in accordance with AS/NZS 2918:2001 install as follows;

-

With heater located in its proposed position, mark a point on the first floor/ceiling that is directly above the centre of heaters flue outlet. Check that the heater’s location allows the FLOOR PENETRATION UNIT to clear all structural floor timbers.

-

Cut a 305mm square or 305mm round hole in floor. (For 150/200/250 FLOOR PENETRATION UNIT). On larger units enlarge hole dimensions accordingly.

-

Measure length from surface of floor to bottom of ceiling below. Adjust the OUTER and INNER CASINGS to confirm the following depending on CEILING PENETRATION TRIM UNIT (CPTU) being used.

(Additional CASINGS may be required to obtain the required length).

Type 1 CPTU (300mm long with 350mm square trim plate). Dimension A + 300mm

Type 2 CPTU (150mm long with 450mm square trim plate). Dimension A + 150mm

-

Secure the OUTER and INNER CASINGS using rivets or self-tapping screws.

NB: for unprotected flue pipe installations or where MESH SCREENS will be fitted the CASINGS

must extend a minimum of 300mm ABOVE floor level. (Order separately from SFP to suit

installation type). -

Fit FLOOR PENETRATION UNIT into hole and secure with screws or nails through flange on unit into floor.

-

Drill (not necessary on pre-punched FLOOR TRIM PLATES) and fasten FLOOR TRIM PLATE to floor using self-tapping screws and spacers. Ensure an even air gap around OUTER CASING of FLOOR PENETRATION UNIT.

NB: 12mm air gap between floor trim plate and floor must be maintained.

-

Remove protective plastic from FLOOR TRIM PLATE (stainless steel plates only)

The FLOOR PENETRATION UNIT is now ready for the fitting of MESH SCREENS or OUTER

CASING and the completion of installation of the FLUE KIT.