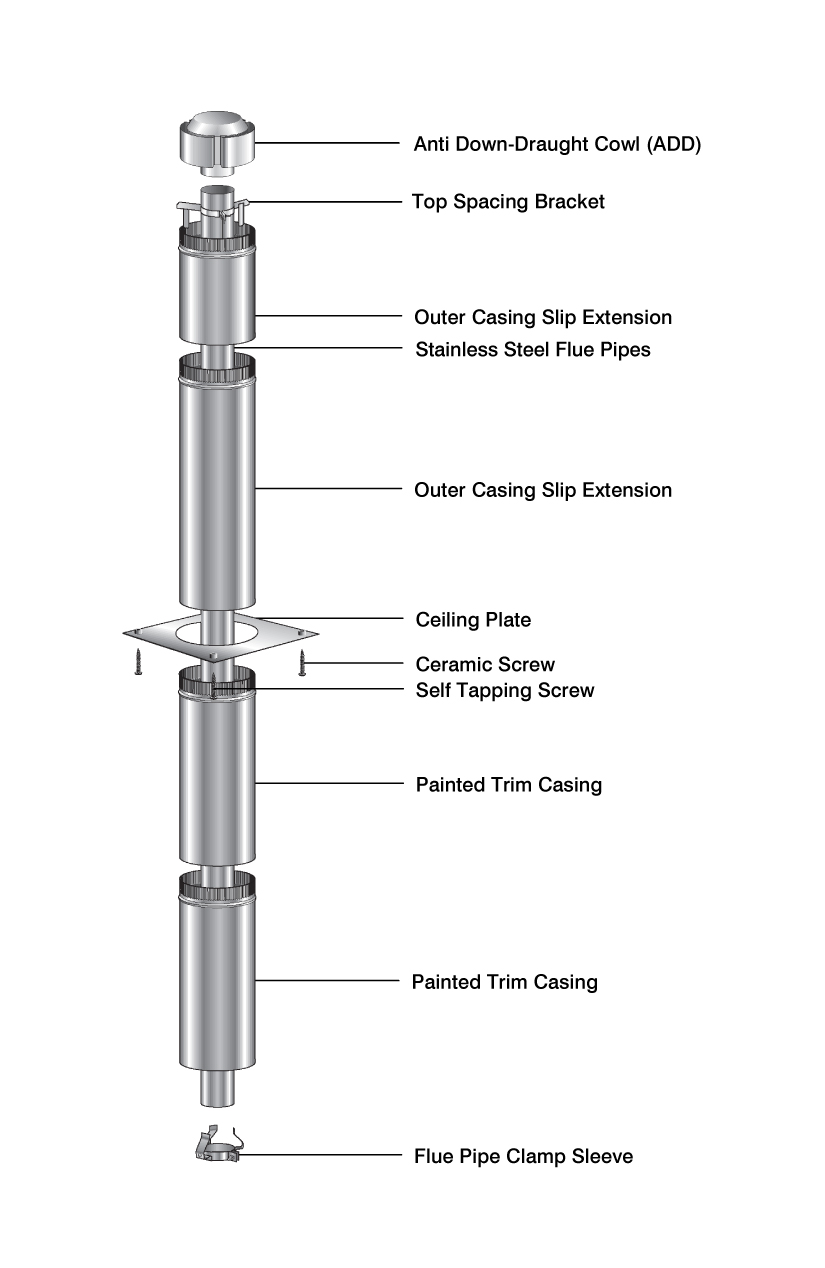

100mm Free Standing Gas Flue Kit Installation Instructions

../Installation Guides/100mm Free Standing Gas Flue Kit Installation Instructions

THIS FLUE KIT HAS BEEN MANUFACTURED IN ACCORDANCE WITH NZS 5261:1996. TO ENSURE SAFETY THIS FLUE KIT MUST BE INSTALLED AS OUTLINED IN THESE INSTRUCTIONS. HEATER AND FLUE CLEARANCES FROM COMBUSTIBLE WALLS MUST BE IN ACCORDANCE WITH HEATER MANUFACTURER'S SPECIFICATIONS AND NZS 5261:1996.

- Locate heater in its proposed position and mark a point on the ceiling that is directly above the centre of the heater’s flue outlet. Check that the heater’s location allows the OUTER CASING to clear all structural roof timbers.

- Cut a 150mm square hole in ceiling. Directly above cut a hole in roof to accommodate OUTER CASING.

- Fit timber nogs around ceiling and roof holes, if necessary.

-

Position the OUTER CASING so that it is flush with the underneath of the ceiling and protrudes through the roof at the required height. When calculating roof penetration height allow for an extra 300mm that can be achieved by using the OUTER CASING SLIP EXTENSION.

The FLUE PIPE is required to be at least 500mm above the nearest point on any part of the roof. It is recommended that in some instances extending the FLUE PIPE above the ridge line will be necessary. Refer to NZS 5261:1996 for more information. Additional CASINGS may have to be added to ensure the correct roof penetration heights are obtained.

- Fix an appropriate flashing around the OUTER CASING to seal onto the roofing material.

- Insert one PAINTED TRIM length into OUTER CASING (with the swaged and crimped end uppermost) a sufficient distance to allow the lower PAINTED TRIM length(s) to be placed over the heater flue stub.

- Fix PAINTED TRIM length together ensuring seams are in line.

- Assemble the 100mm stainless steel FLUE PIPES together ensuring all seams are in line using 3 pop rivets or screws and seal.

- Fit SPACER BRACKETS to FLUE PIPE if necessary to maintain air gap between FLUE PIPES and OUTER CASING or FLUE TRIM.

- Lift PAINTED TRIM lengths sufficiently to insert CEILING PLATE over heater flue spigot, ensuring the folded edge upstands are facing the ceiling.

- Fasten CEILING PLATE to ceiling using screws and spacers provided. Ensure an even gap around FLUE TRIM when fixing.

- Lower stainless steel FLUE PIPES from the roof into the OUTER CASING (crimped ends towards the heater) and into the heaters flue outlet. Lift FLUE TRIM for access and seal FLUE to heater stub.

- Lower FLUE TRIM into position on top of heater.

- Before securing the SLIP EXTENSION OUTER CASING to the OUTER CASING ensure the FLUE PIPE extends above the top of the SLIP EXTENSION OUTER CASING by a maximum of 25mm. adjust SLIP EXTENSION to obtain this measurement.

- Fix TOP SPACER BRACKET to the FLUE PIPE making sure lugs fit snugly inside OUTER CASING or SLIP EXTENSION if used. Make sure TOP SPACER BRACKET fits down hard into the SLIP EXTENSION/OUTER CASING.

- Fit GAS COWL into FLUE PIPE pushing down fully onto TOP SPACER BRACKET.

N.B it is the responsibility of the installer to ensure that the installation of this flue kit complies with the appliance manufacturers specifications for the flue pipes and that relevant Local Body requirements are adhered to.